Products

Long

Products Steel

Our Products

The Steel Dynamics Long Products Group produces a variety of hot rolled steel products. The Long Products Group is comprised of four electric arc furnace steel mills – Columbia City, Indiana; Pittsboro, Indiana; Roanoke, Virginia; and Huntington, West Virginia – which have a combined annual production capacity of 4.1 million tons of hot rolled steel as well as four downstream processing and/or value-add facilities. These facilities are in Colton, KY; Wurtland, KY; Memphis, TN; and Pelham, AL.

Contact

Lorem ipsum dolor sit amet, consectetur adipiscing.

Firstname Lastname

123-456-7890

Inquiries

End Markets

Steel produced by the Steel Dynamics Long Products Group is used in several end markets including but not limited to automotive, agricultural, energy, construction, solar, OEM, heavy construction equipment, transportation equipment, manufacturing equipment, oilfield, military, infrastructure, and Railroads. Given the extremely high content of recycled steel used in electric-arc furnace steelmaking, SDI-produced steel is particularly well-suited to applications where conformance to LEED and Green Building guidelines is a consideration.

Automotive

Agriculture

Solar

Constuction

Oilfield

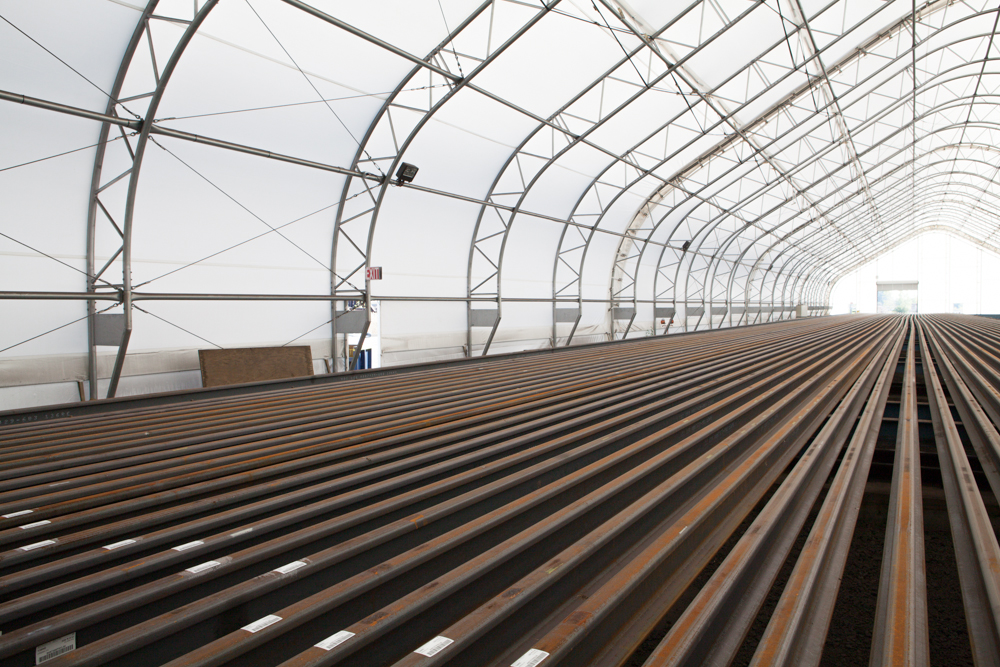

Structural and Rail Division

Our Structural and Rail Division is located in Columbia City, Indiana. It began operations as a Structural mill in 2002 and is one of SDI’sl argest steel operations. The Structural mill produces a variety of parallel flange sections such as wide flange beams, American Standard Beams, Manufactured Housing Beams, H Piling and Channel sections for the construction, transportation and industrial machinery markets.

Engineered Bar Products Division

Our Engineered Bar Products Division is located in Pittsboro, Indiana. One of the largest engineered bar mills in North America, our facility is capable of producing a broad array of engineered special bar quality (SBQ), merchant bar quality (MBQ), and reinforcing bar products.

Roanoke Bar Division

Our primary merchant bar producing mill, our Roanoke Bar Division, is located in Roanoke, Virginia. Originally constructed in the mid-1950s and purchased from Roanoke Electric in 2006, several key upgrades in equipment and technology have proven to be keen capital expenditures. Today, the mill consists of an electric arc furnace, a ladle metallurgy furnace, a five-strand continuous caster capable of casting up to 6 inch square billets, a reheat furnace, and a rolling mill with automatic in-line straightening, shearing and bundling capabilities.

Steel of West Virginia Division

Considered the “artisans of steel”, Steel of West Virginia is our specialty steelmaking facility. We manufacture a variety of special shapes for use in specific applications. Our goal is to help our customers design the exact type of steel shape they need that meets their requirement for a particular application. We deliver custom-produced products to our customers that can be placed directly into their assembly operations.

Vulcan Steel Division

When Vulcan Threaded Rod was founded in 1978, the goal was simple: to provide fastener distributors in the South with threaded rod along with outstanding service at a competitive price. Over time, Vulcan grew to become the dominant player in the threaded rod market nationwide. Vulcan entered the long bar quench and temper market and now the Heat Treating division is the largest long bar, induction heat treater in the world with annual capacity surpassing 100,000,000 lbs. on five state of the art induction furnaces.